Metal Stamping Technology Market Size, Share, Growth & Industry Analysis, By Technology (Progressive Die Stamping, Rotary Die Stamping, Fine Blanking), By Material Type (Steel, Aluminum, Copper, Brass, Others), By Application (Automotive, Aerospace, Electronics, Industrial Equipment, Medical, Others), and Regional Analysis, 2024-2031

Metal Stamping Technology Market: Global Share and Growth Trajectory

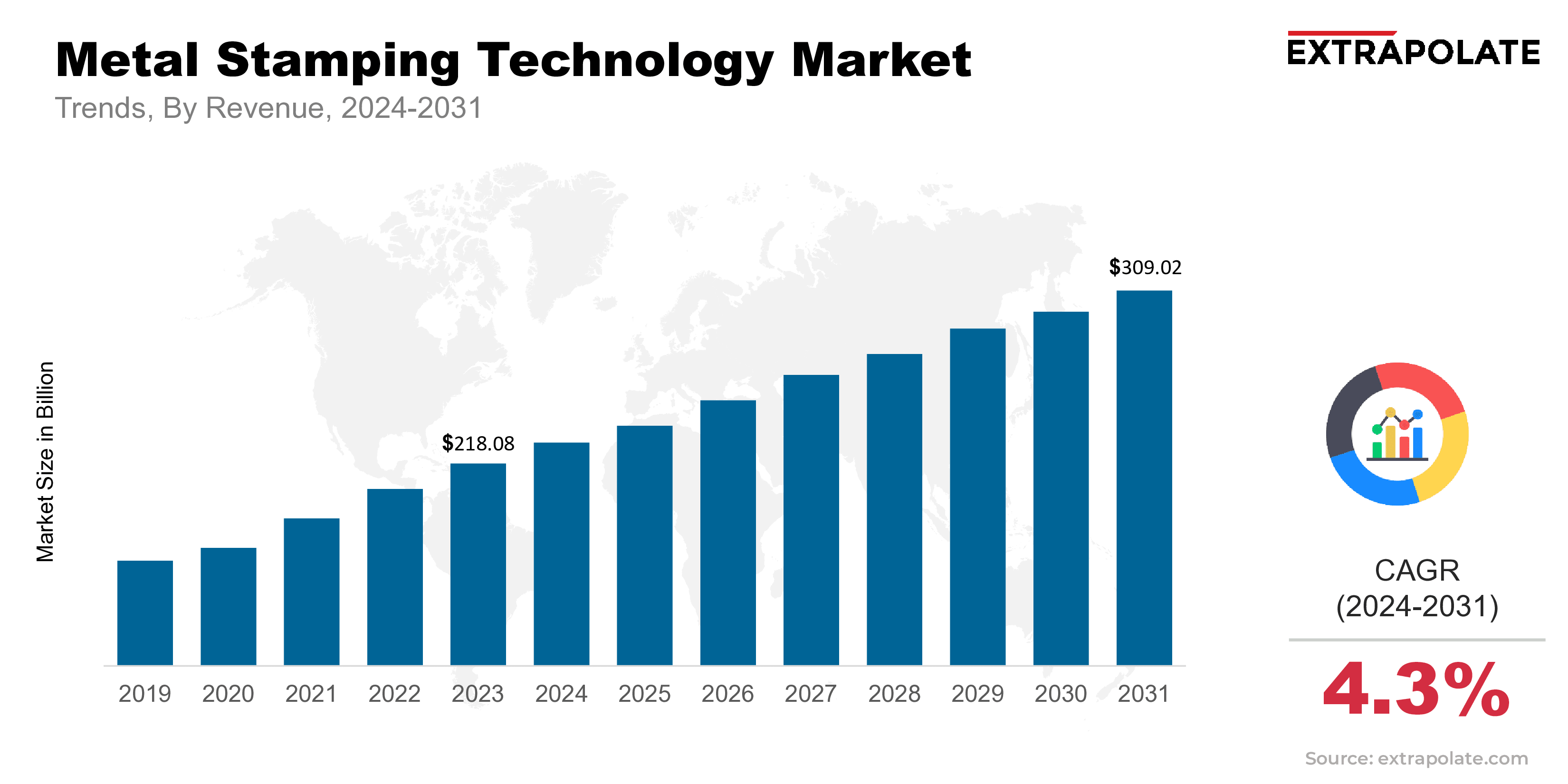

Global Metal Stamping Technology Market size was recorded at USD 218.08 billion in 2023, which is estimated to be valued at USD 229.46 billion in 2024 and reach USD 309.02 billion by 2031, growing at a CAGR of 4.3% during the forecast period.

The global market is experiencing substantial growth, driven by advancements in manufacturing processes, the increasing demand for high-precision components, and the expansion of end-use industries such as automotive, electronics, and aerospace.

Metal stamping is a widely used manufacturing process that involves the shaping of metal sheets into specific parts and components using dies and presses. With the increasing need for lightweight and durable metal parts, particularly in the automotive and electronics sectors, the demand for metal stamping technology is on the rise.

This market includes various types of metal stamping techniques such as progressive stamping, deep drawing, and rotary stamping, each designed to cater to specific manufacturing needs. As industries continue to seek faster, more efficient, and cost-effective production methods, metal stamping technology is evolving to incorporate automation, robotics, and artificial intelligence.

These innovations are enabling higher precision, faster production rates, and reduced waste, making the technology increasingly attractive to manufacturers. The automotive industry remains one of the largest consumers of metal stamping technology, as manufacturers demand high-quality, lightweight parts to meet fuel efficiency and safety requirements.

Additionally, the growing demand for consumer electronics, where high-precision metal components are essential for the functionality and aesthetic of devices, is also fueling the growth of the market.

Technological advancements such as the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) are enhancing the precision and complexity of metal stamping processes, allowing manufacturers to produce more intricate and customized parts. The market is also witnessing a shift towards sustainable practices, with manufacturers investing in energy-efficient stamping machines and recycling metal scrap to reduce environmental impact.

As the need for more efficient and reliable manufacturing solutions grows, the market is expected to continue its upward trajectory. The combination of increasing demand from key industries, advancements in technology, and the push for sustainability will drive innovation and market expansion in the coming years.

Key Market Trends Driving Product Adoption

The metal stamping technology market is marked by continuous innovation and growing demand across various industries. Key trends driving market growth include:

- Automotive Industry Demand: The automotive sector remains a primary driver, with the need for lightweight, durable, and cost-effective parts increasing the adoption of metal stamping.

- Advancements in Automation: Automation is enhancing the efficiency and precision of stamping processes, leading to reduced labor costs and faster production cycles.

- Integration with Industry 4.0: The integration of metal stamping technologies with smart manufacturing systems is enabling real-time monitoring, predictive maintenance, and improved process control.

- Sustainability and Material Efficiency: Growing environmental concerns are pushing manufacturers to adopt stamping processes that reduce material waste and enhance energy efficiency.

- Customization and Precision: As industries demand increasingly complex and customized components, metal stamping technology is evolving to meet these requirements, offering high precision and scalability.

Major Players and Their Competitive Positioning

The metal stamping technology industry is led by a few key players, including companies like Aida Engineering, Schuler Group, and Amada Co., Ltd. These companies are investing in cutting-edge technologies to enhance stamping capabilities and expand their market presence. Smaller players are also emerging with specialized offerings targeting niche industries.

Consumer Behavior Analysis

Consumers are driving the adoption of metal stamping technology for the following reasons:

- Cost-Efficiency: Metal stamping processes offer cost-effective solutions for producing large quantities of metal parts.

- Durability and Performance: The demand for high-performance, durable parts is accelerating the use of metal stamping in critical industries.

- Complex Design Capabilities: As industries require increasingly intricate designs, metal stamping provides a solution for producing complex shapes with high precision.

- Environmental Sustainability: The industry's move towards sustainable practices, such as reducing waste and energy consumption, is boosting demand for eco-friendly stamping solutions.

Pricing Trends

Pricing trends in the metal stamping technology industry are influenced by factors such as the complexity of the design, the material used, and the volume of production. High-volume, simple parts tend to be less expensive due to economies of scale, while custom, intricate designs or specialty materials can command higher prices.

Growth Factors

Several factors are driving the growth of the metal stamping technology market:

- Rising Industrial Demand: Industry's rise especially in economies that develop, pushes demand for stamped metal parts. Many industries need them. Parts like these appear in automobiles, appliances along with electronics. Because of this the market expands.

- Technological Advancements: Automation and the integration of Industry 4.0 technologies are improving efficiency, accuracy, and cost-effectiveness in metal stamping.

- Demand for Lightweight Components: Cars and planes utilize more and more pressed pieces. These components yield parts that are both light and tough - this fuels market expansion.

- Customization Needs: The shift towards more customized, precision-engineered components in various industries is encouraging the adoption of advanced stamping techniques.

Regulatory Landscape

Rules about metal stamping tools change. They feature strict guidelines related to how the job affects the environment, which materials are acceptable and what keeps workers safe. Companies observe these rules to keep running also keep people confident in their work. Makers follow worldwide rules for superior products and safe workspaces.

Recent Developments

The metal stamping technology market is continuously evolving with new innovations:

- Advanced Materials: The development of new, high-performance materials for stamping is enabling manufacturers to produce more durable and lightweight parts.

- Robotic Integration: Robots now form a part of the stamping process. They boost precision plus cut down on mistakes made by people - the machines also improve how good the product is besides how fast it comes out.

- Energy-Efficient Technologies: Manufacturers are adopting energy-efficient stamping processes that minimize waste and reduce operational costs.

Current and Potential Growth Implications

Demand-Supply Analysis

More and more people want metal stamping technology. The desire for exact, cheap parts by many fields fuels this rise. But issues with supply, for example, when there isn't enough raw material, could slow the expansion of the market - these factors represent a possible limitation.

Gap Analysis

While the metal stamping technology market is evolving, there are still areas for improvement:

- Sustainability in Production: Manufacturers need to further reduce energy consumption and material waste during the stamping process.

- Adaptability to New Materials: More industries now use composite materials. Because of this metal stamping must change. The process must become suitable for the creation of components with these substances - a process adapted to them.

- Integration with Advanced Manufacturing: To stay competitive, metal stamping must integrate with emerging technologies such as 3D printing and additive manufacturing.

Top Companies in the Metal Stamping Technology Market

- Aida Engineering

- Schuler Group

- Amada Co., Ltd.

- Protolabs, Inc.

- Tower International, Inc.

- Kawasaki Heavy Industries, Ltd.

- Mitsubishi Heavy Industries, Ltd.

Metal Stamping Technology Market: Report Snapshot

Segmentation | Details |

By Technology | Progressive Die Stamping, Rotary Die Stamping, Fine Blanking |

By Material Type | Steel, Aluminum, Copper, Brass, Others |

By Application | Automotive, Aerospace, Electronics, Industrial Equipment, Medical, Others |

By Region | North America, Europe, Asia-Pacific, Middle East & Africa, South America |

High Growth Segments

- Automotive: Increasing demand for lightweight, durable parts for vehicles is driving the use of metal stamping technology in the automotive sector.

- Aerospace: Demand for parts crafted with great accuracy fuels progress in the airplane business.

- Electronics: The electronics industry continues to adopt metal stamping for producing components with intricate designs and high precision.

Major Innovations

Innovation is key to staying competitive in the metal stamping technology market. Some of the latest innovations include:

- Hydraulic Presses: Superior hydraulic presses improve the exactness and swiftness of stamping. These advances allow for tighter tolerances besides faster cycle times. They also let producers make complex parts effectively. These presses are critical for industries requiring high-volume, precise components. The outcome is fewer defects plus better production rates, which lowers costs and raises the overall value. .

- Laser Cutting Technology: The integration of laser cutting with stamping processes is enabling manufacturers to produce complex parts with greater efficiency.

- Robotic Integration: Robotic systems see increased usage in stamping operations. This boosts uniformity plus cuts down on mistakes made by people. The application of these automated mechanisms in manufacturing produces parts of equal quality - the kind one desires to see with an efficient workflow.

Potential Growth Opportunities

- Intense Competition: The market is highly competitive, with established players and emerging companies vying for market share.

- Technological Advancements: Businesses need to innovate regularly - this helps them beat competitors. Innovation also addresses shifting requirements in diverse business fields.

- Supply Chain Challenges: Disruptions in the supply of raw materials and components can hinder production and affect market dynamics.

Extrapolate Research says:

The global market for metal stamping technology should grow steadily. Technological advances, a rise in request across multiple sectors and a pursuit of improved accuracy and tailoring will fuel this rise. But businesses which innovate, boost productivity along with adjust to new tendencies will have an advantage in this active marketplace - they will likely prosper.

ARE YOU SEEKING COMPREHENSIVE INSIGHT ON VARIOUS

MARKETS?

CONTACT OUR EXPERTS TODAY

Metal Stamping Technology Market Size

- April-2025

- 148

- Global

- machinery-equipment

Related Research

0-Global Market Status and Trend Report 2015-2026

November-2020

2 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020

3 Side Seal Machines-Global Market Status & Trend Report 2022-2030 Top 20 Countries Data

December-2020